ORGANISATION NAME: ICF (INTEGRAL COACH FACTORY), CHENNAI

Date: September 23th, 2022

Time: 10.30 A.M- 2.30 P.M

Venue: INTEGRAL COACH FACTORY

ABOUT INDUSTRIAL VISIT

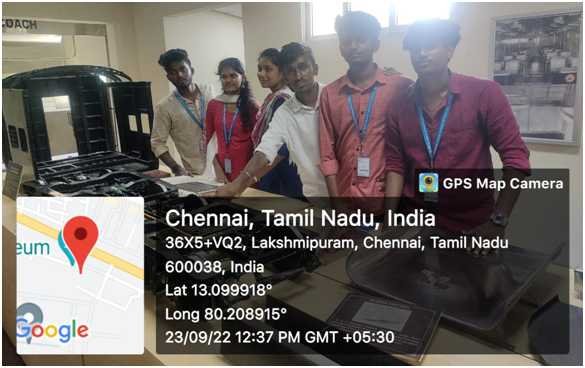

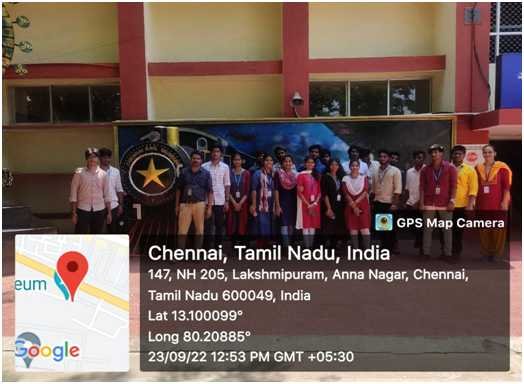

Industrial visit was arranged at ICF (INTEGRAL COACH FACTORY), in CHENNAI on 23.09.2022. The main objective of the visit is to make the students aware of various activities related to furnishing works for manufacturing rail coaches. We (faculty) along with 75 students started from the college for the visit at 8.30 a.m. and reached ICF at 9.30 a.m after the speech about safety precaution and need of Industrial visit by DEAN E&T. The company is located at perambur in Chennai. As soon as we reached the company we were guided by Chennai rail museum co-coordinator.

ABOUT THE COMPANY

Integral Coach Factory, Chennai, is a premier Production Unit of Indian Railways manufacturing passenger coaches. ICF is the first of its kind to be established after Independence for the manufacture of light weight, all steel and all welded Integral railway passenger coaches. The factory was set up in 1955 with Swiss collaboration. ICF continues to experiment with design & development of new type coaches such as self propelled and other special type coaches.The Maintenance and Construction Organisation is headed by Chief Electrical General Engineer. Chief Electrical Engineer/Quality Control and Commissioning is responsible for Inspection and Quality Assurance of the components and coaches.

- Designs- The Electrical Design Wing is responsible for evolving new designs of coaches, equipments and sub systems, drawings and specifications for components and assemblies. The Design Wing is also responsible for issuing necessary interfaces for electrical equipments for incorporation in the Shell design and inputs required for Production Wing. This wing is also responsible for developing expertise in design of new generation self-propelled coaches, EMUs, DEMUs, Air-conditioned, Non Air-conditioned coaches and Luxury Trains for user Railways.

b. Production ? The Production Wing is responsible for manufacturing of harness, installation of electrical equipments, wiring and complete electrical furnishing of the various types of coaches. The Production wing has developed the expertise in handling of different types of self-propelled coaches including 3 phase AC DC EMUs, EMUs, DEMUs, Ac & non AC coaches including luxury trains for RTDC & IRCTC.

c. Inspection – The Inspection Wing is responsible for Quality assurance of electrical components and systems used for manufacturing of the coaches. This Wing is also responsible for undertaking prototype inspection of newly developed components/equipments. This Wing is also responsible for testing and commissioning of self-propelled coaches and AC coaches to ensure quality and reliability.

d. Contracts and Development- The Contracts & Development Wing is responsible for liaising with the purchase department for ensuring timely availability of materials for coach production, customer complaint redressal and discharge of warranty obligations, failure analysis and corrective and preventive actions, development of new Items for coach production and development of additional sources for limited source items.

e. Maintenance – The Maintenance Wing is responsible for maintenance of Plant & Machinery including numerically controlled & CNC machines, EOT cranes etc. This Wing is also responsible for maintaining power supply for Factories, ie. Shell & Furnishing, D&D Wing, Hospital, Colony etc. The construction activities associated with new projects, safety works and replacement works of Plant & Machinery are also undertaken by this Wing. This Wing also is undertaking number of green energy projects such as installation of Wind Mill and Solar energy systems

DESIGN FEATURES

The design concept of the coach stipulates that the roof, side wall, end wall and the underframe are joined together by welding, to form a fully integral coach shell. The end-wall construction has been made especially strong to make it anti-telescopic to ensure maximum safety to passengers. Further, crashworthy features are provided with CBC design to minimize impact on passengers during accidents/derailments.

From the basic design handed down by the collaborators, ICF has diversified having established its expertise and skill in this field, to design and manufacture more than 350 different types of coaches for Indian Railways and export market. Every time a new type of coach is launched, emphasis is laid on improving passenger comfort, passenger safety and higher speeds. ICF follows standard inspection procedures to ensure quality from raw material stage to the finished coach.

ICF has endeavoured to meet passengers expectations through innovations like

- Cushioned seats in General Second Class and SLR coaches

- Provision of Controlled Discharge Toilet Systems

- Anti-injury features in the passenger areas of A/C 2-tier and Sleeper coaches

- Enhanced carrying capacity in A/C 2-tier, First A/C and Garib Rath Chair Car

- Provision of forced ventilation, PIS/PAS in AC/DC EMUs for WR and CR

- UIC vestibules in mainline coaches

- Disabled friendly features in SLRD/SRD coaches

- Modular toilets in passenger coaches

- Stainless steel paneling, handholds in EMUs

- Provision of laptop and cell phone charging points in passenger coaches

- Use of stainless steel in Pantry Cars including interiors and the equipment

STUDENT FEEDBACK

The session was highly informative and interesting. This visit will be very useful for carrying out our project work.