07.05.2020

10 AM TO 1.00 PM.

SPEAKERS:

Dr. K.N.Srinivas, HOD/EEE and Vice-Principal (Academic),

Dr. S.Gayathri Monicka.Prof/EEE

Mr.K.Arulvendhan.A.P/EEE

MODERATOR

Mr. Dillisrinivasan.

Audience: +2 And Final Year EEE Diploma students

CONTENTS

- Why EV?

- History of EV

- Key Components of Electric Vehicle

1. Charger

2. Battery & Battery Management System

3. Electric Machine

4. Power Converters

- Types of Electric Vehicles

1. Battery Electric Vehicle

2. Hybrid Electric Vehicle

3. Plug-In Hybrid Vehicle

4. Fuel Cell Electric Vehicle

5. Solar Electric Vehicle

- Opportunities and Future of EV in India:

- Battery Technology

- Types of battery

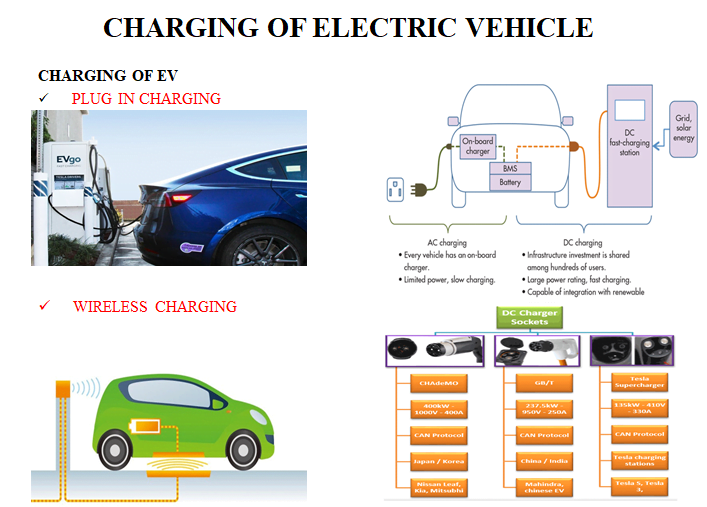

- Types of Charging

- Market overview

- E-Mobility

- Smart cities and IOT

- Why EV?

It is a vehicle which has following features

- Portable energy source

- Traction effort provided by electric motor

- EVs emit ~66% less carbon dioxide compared to petrol/diesel vehicles.

- Electricity used to charge an EV can come from renewable sources like solar, wind and geothermal.

- EVs trend towards more eco-friendly production and recycled or green materials.

- Cheaper to Run.

Owners of an EV have the advantage of much lower running costs. The electricity to charge an EV works out around a third as much per kilometre as buying petrol for the same vehicle

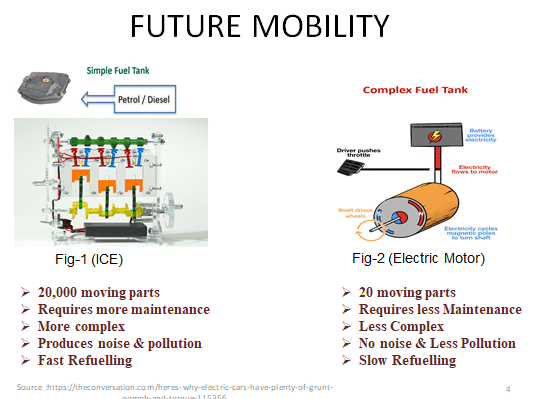

- Cheaper to Maintain.

A battery electric vehicle (BEV) has a lot less moving parts than a conventional petrol/diesel car. There is relatively little servicing and no expensive exhaust systems, starter motors, fuel injection systems, radiators and many other parts that aren’t needed in an EV.

- Less pollution: By choosing to drive an EV you are helping to reduce harmful air pollution from exhaust emissions. An EV has zero exhaust emissions.

- Renewable energy: If you use renewable energy to recharge your EV, you can reduce your greenhouse gas emissions even further. You could recharge your EV from your solar PV system during the day instead of from the grid. Another idea is to purchase Green Powerfrom your electricity retailer. Then, even if you recharge your EV from the grid, your greenhouse gas emissions are reduced.

- Eco-friendly materials: There is also a trend towards more eco-friendly production and materials for EVs. The Ford Focus Electric is made up of recycled materials and the padding is made out of bio based materials. The Nissan Leaf’s interior and bodywork are partly made out of green materials such as recycled water bottles, plastic bags, old car parts and even second hand home appliances.

- Health Benefits

Reduced harmful exhaust emissions is good news for our health. Better air quality will lead to less health problems and costs caused by air pollution. EVs are also quieter than petrol/diesel vehicles, which means less noise pollution.

History of EV:

- 1830’s – First electric carriage was built

- 1891 – First electric automobile was built in the United States

- 1900 – Heyday

- 1908 – Henry Ford introduces Model T

- 1974 -Vanguard-Sebring’s

Figure: T model and Vanguard Electric Car

- What is an EV?

An electric vehicle (EV) is one that operates on an electric motor, instead of an internal-combustion engine that generates power by burning a mix of fuel and gases. Therefore, such as vehicle is seen as a possible replacement for current-generation automobile, in order to address the issue of rising pollution, global warming, depleting natural resources, etc.Though the concept of electric vehicles has been around for a long time, it has drawn a considerable amount of interest in the past decade amid a rising carbon footprint and other environmental impacts of fuel-based vehicles.

Components of Electric Vehicle

Charging port or vehicle inlet: It is a connector present on the electric vehicle to allow it to be connected to an external source of electricity for charging.

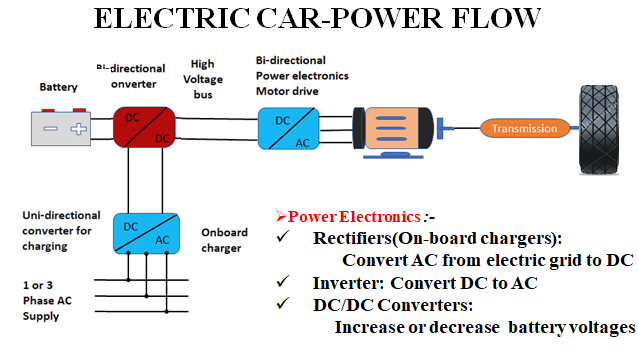

Power electronic converter: A power electronic converter is made of high power fast-acting semiconductor devices, which act as high-speed switches. Different switching states alter the input voltage and current through the use of capacitive and inductive elements. The result is an output voltage and current, which is at a different level to the input.

On-board charger: It is an AC-to-DC power electronic converter (often referred to as a rectifier) that takes the incoming AC electricity supplied via the charge port and converts it to DC power for charging the traction battery. Using the battery management system, it regulates the battery characteristics such as voltage, current, temperature, and state of charge.

Traction battery pack: It is a high voltage battery used to store energy in the electric car and provide power for use by the electric traction motor.

Battery power converter: It is a DC-to-DC power electronic converter that converts the voltage of the traction battery pack to the higher-voltage of the DC-bus used for power exchange with the traction motor.

Motor drive: It is a DC-to-AC (often referred to as inverter or the variable frequency drive) or at times a DC-to-DC power electronic converter, used to convert power from the high voltage DC bus to AC (or at times DC) power for the operation of motor. The converter is bidirectional for operating in both driving and regenerative braking mode.

Traction electric motor/generator: It is the main propulsion device in an electric car that converts electrical energy from the traction battery to mechanical energy for rotating the wheels. It also generates electricity by extracting energy from the rotating wheels while braking, and transferring that energy back to the traction battery pack.

Transmission: For an electric car, usually a single gear transmission with differential is used to transfer mechanical power from the traction motor to drive the wheels.

Power electronics controller: This unit controls the flow of electrical power in the different power electronic converters in the electric car.

Battery (auxiliary): In an electric drive vehicle, the auxiliary battery provides electricity to start the car before the traction battery is engaged and is also used to power the vehicle accessories.

Batteries for Electric Vehicles

Most plug-in hybrids and all-electric vehicles use lithium-ion batteries like these.

Energy storage systems, usually batteries, are essential for hybrid electric vehicles (HEVs), plug-in hybrid electric vehicles (PHEVs), and all-electric vehicles (EVs).

TYPES OF ENERGY STORAGE SYSTEMS

The following energy storage systems are used in HEVs, PHEVs, and EVs.

Lithium-Ion Batteries

Lithium-ion batteries are currently used in most portable consumer electronics such as cell phones and laptops because of their high energy per unit mass relative to other electrical energy storage systems. They also have a high power-to-weight ratio, high energy efficiency, good high-temperature performance, and low self-discharge. Most components of lithium-ion batteries can be recycled, but the cost of material recovery remains a challenge for the industry. Most of today’s PHEVs and EVs use lithium-ion batteries, though the exact chemistry often varies from that of consumer electronics batteries. Research and development are ongoing to reduce cost and extend their useful life.

Nickel-Metal Hydride Batteries

Nickel-metal hydride batteries, used routinely in computer and medical equipment, offer reasonable specific energy and specific power capabilities. Nickel-metal hydride batteries have a much longer life cycle than lead-acid batteries and are safe and abuse tolerant. These batteries have been widely used in HEVs. The main challenges with nickel-metal hydride batteries are their high cost, high self-discharge and heat generation at high temperatures, and the need to control hydrogen loss.

Lead-Acid Batteries

Lead-acid batteries can be designed to be high power and are inexpensive, safe, and reliable. However, low specific energy, poor cold-temperature performance, and short calendar and cycle life impede their use. Advanced high-power lead-acid batteries are being developed, but these batteries are only used in commercially available electric-drive vehicles for ancillary loads.

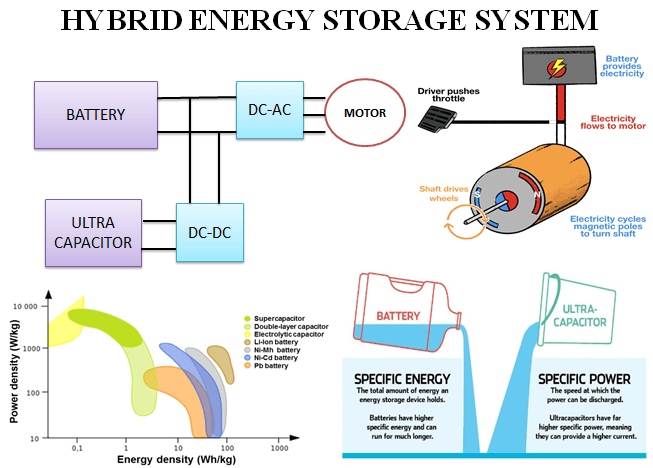

Ultra capacitors

Ultracapacitors store energy in a polarized liquid between an electrode and an electrolyte. Energy storage capacity increases as the liquid’s surface area increases. Ultracapacitors can provide vehicles additional power during acceleration and hill climbing and help recover braking energy. They may also be useful as secondary energy-storage devices in electric-drive vehicles because they help electrochemical batteries level load power.

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Power Electronics for Electric Vehicle

DC-DC Converter

A DC-to-DC converter is an electronic circuit or electromechanical device that converts a source of direct current (DC) from one voltage level to another. It is a type of electric power converter. Power levels range from very low (small batteries) to very high (high-voltage power transmission).

Inverter

A power inverter, or inverter, is a power electronic device or circuitry that changes direct current (DC) to alternating current (AC). The input voltage, output voltage and frequency, and overall power handling depend on the design of the specific device or circuitry.

Rectifier

A rectifier is an electrical device that converts alternating current (AC), which periodically reverses direction, to direct current (DC), which flows in only one direction. The process is known as rectification, since it “straightens” the direction of current.

VARIOUS TYPES OF ELECTRIC MOTORS USED IN ELECTRIC VEHICLES

- Brushless DC Motor

- Permanent Magnet Synchronous Motor (PMSM)

- Three Phase AC Induction Motors

- Switched Reluctance Motors (SRM)

1. Brushless DC Motors

It is similar to DC motors with Permanent Magnets. It is called brushless because it does not have the commutator and brush arrangement. The commutation is done electronically in this motor because of this BLDC motors are maintenance free. BLDC motors have traction characteristics like high starting torque, high efficiency around 95-98%, etc. BLDC motors are suitable for high power density design approach. The BLDC motors are the most preferred motors for the electric vehicle application due to its traction characteristics.

2. Permanent Magnet Synchronous Motor (PMSM)

This motor is also similar to BLDC motor which has permanent magnets on the rotor. Similar to BLDC motors these motors also have traction characteristics like high power density and high efficiency. The difference is that PMSM has sinusoidal back EMF whereas BLDC has trapezoidal back EMF. Permanent Magnet Synchronous motors are available for higher power ratings. PMSM is the best choice for high performance applications like cars, buses. Despite the high cost, PMSM is providing stiff competition to induction motors due to increased efficiency than the latter. PMSM is also costlier than BLDC motors. Most of the automotive manufacturers use PMSM motors for their hybrid and electric vehicles. For example, Toyota Prius, Chevrolet Bolt EV, Ford Focus Electric, zero motorcycles S/SR, Nissan Leaf, Hinda Accord, BMW i3, etc use PMSM motor for propulsion.

3. Three Phase AC Induction Motors

The induction motors do not have a high starting toque like DC series motors under fixed voltage and fixed frequency operation.

But this characteristic can be altered by using various control techniques like FOC or v/f methods. By using these control methods, the maximum torque is made available at the starting of the motor which is suitable for traction application. Squirrel cage induction motors have a long life due to less maintenance. Induction motors can be designed up to an efficiency of 92-95%. The drawback of an induction motor is that it requires complex inverter circuit and control of the motor is difficult.

4. Switched Reluctance Motors (SRM)

Switched Reluctance Motors is a category of variable reluctance motor with double saliency. Switched Reluctance motors are simple in construction and robust. The rotor of the SRM is a piece of laminated steel with no windings or permanent magnets on it. This makes the inertia of the rotor less which helps in high acceleration. The robust nature of SRM makes it suitable for the high speed application. SRM also offers high power density which are some required characteristics of Electric Vehicles. Since the heat generated is mostly confined to the stator, it is easier to cool the motor. The biggest drawback of the SRM is the complexity in control and increase in the switching circuit. It also has some noise issues. Once SRM enters the commercial market, it can replace the PMSM and Induction motors in the future.

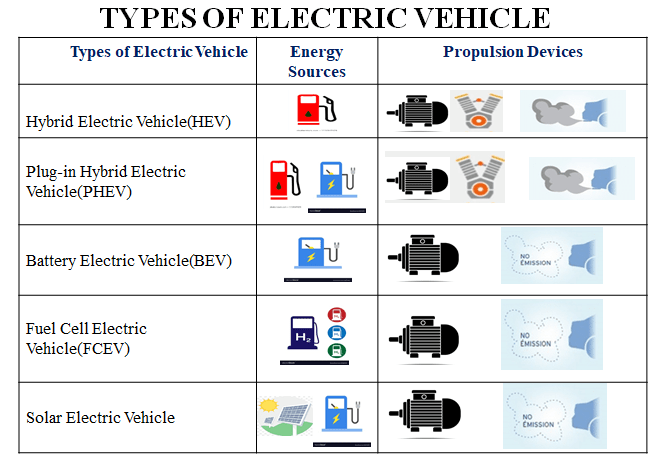

TYPES OF ELECTRIC VEHICLES

There are three main types of electric vehicles (EVs), classed by the degree that electricity is used as their energy source. BEVs, or battery electric vehicles, PHEVs of plug-in hybrid electric vehicles, and HEVs, or hybrid electric vehicles. Only BEVs are capable of charging on a level 3, DC fast charge.

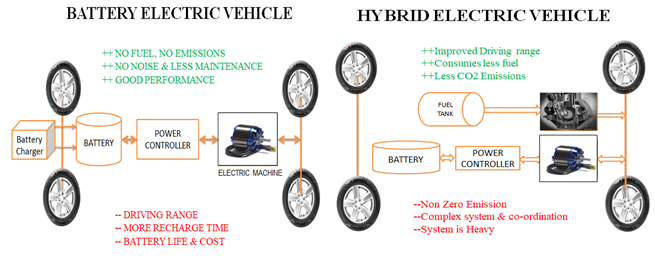

Battery Electric Vehicles (BEV)

Battery Electric Vehicles, also called BEVs, and more frequently called EVs, are fully-electric vehicles with rechargeable batteries and no gasoline engine. Battery electric vehicles store electricity onboard with high-capacity battery packs. Their battery power is used to run the electric motor and all onboard electronics. BEVs do not emit any harmful emissions and hazards caused by traditional gasoline-powered vehicles. BEVs are charged by electricity from an external source. Electric Vehicle (EV) chargers are classified according to the speed with which they recharge an EVs battery.

Hybrid Electric Vehicles (HEV)

HEVs are powered by both gasoline and electricity. The electric energy is generated by the car’s own braking system to recharge the battery. This is called ‘regenerative braking’, a process where the electric motor helps to slow the vehicle and uses some of the energy normally converted to heat by the brakes. HEVs start off using the electric motor, then the gasoline engine cuts in as load or speed rises. The two motors are controlled by an internal computer, which ensures the best economy for the driving conditions.

HEV Examples

- Toyota Prius Hybrid

- Honda Civic Hybrid

- Toyota Camry Hybrid

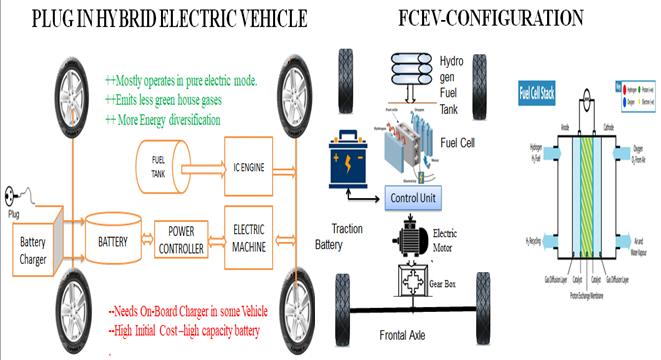

Plug-in Hybrid Electric Vehicle (PHEV)

Plug-in Hybrid Electric Vehicles or PHEVs can recharge the battery through

both regenerative braking and “plugging in” to an external source of electrical power. While “standard” hybrids can (at low speed) go about 1-2 miles before the gasoline engine turns on, PHEV models can go anywhere from 10-40 miles before their gas engines provide assistance.

PHEV Examples

- Chevy Volt

- Chrysler Pacifica

- Ford C-Max Energy

Fuel Cell Electric Vehicle (FCEV)

- FCEVs use a propulsion system similar to that of electric vehicles, where energy stored as hydrogen is converted to electricity by the fuel cell. Unlike conventional internal combustion engine vehicles, they produce no harmful tailpipe emissions. Other benefitsinclude increasing U.S. energy security and strengthening the economy.

- FCEVs are fueled with pure hydrogen gas stored in a tank on the vehicle. Similar to conventional internal combustion engine vehicles, they can fuel in less than 5 minutesand have a driving range over 300 miles. FCEVs are equipped with other advanced technologies to increase efficiency, such as regenerative braking systems, which capture the energy lost during braking and store it in a battery. Major automobile manufacturers are offering a limited but growing number of production FCEVs to the public in certain markets, in sync with what the developing infrastructure can support.

Opportunities and Future of EV in India:

Over the past several decades, the number of electric vehicles (EVs) has continued to increase. in worldwide, Projections estimate more than 125 million EVs will be on the road by 2030.

The Shift to electric mobility has become necessary on account of fast depletion of Fossil fuels, rapid increase in energy cost, impact of transportation on the environment and concern over climate change.

As the entire country observed ‘lockdown’ on March 22, there was a significant dip in air pollution levels across the country. Delhi, Chennai, Bengaluru, Kolkata and Lucknow witnessed clean air as the Air Quality Index stayed within two digits.

This is because of the reduction of private vehicles, other non-essential transportation, no construction activity has all contributed to improvement in air quality. Understanding how an electric vehicle works is actually much simpler than understanding how a gas -or diesel powered cars works.

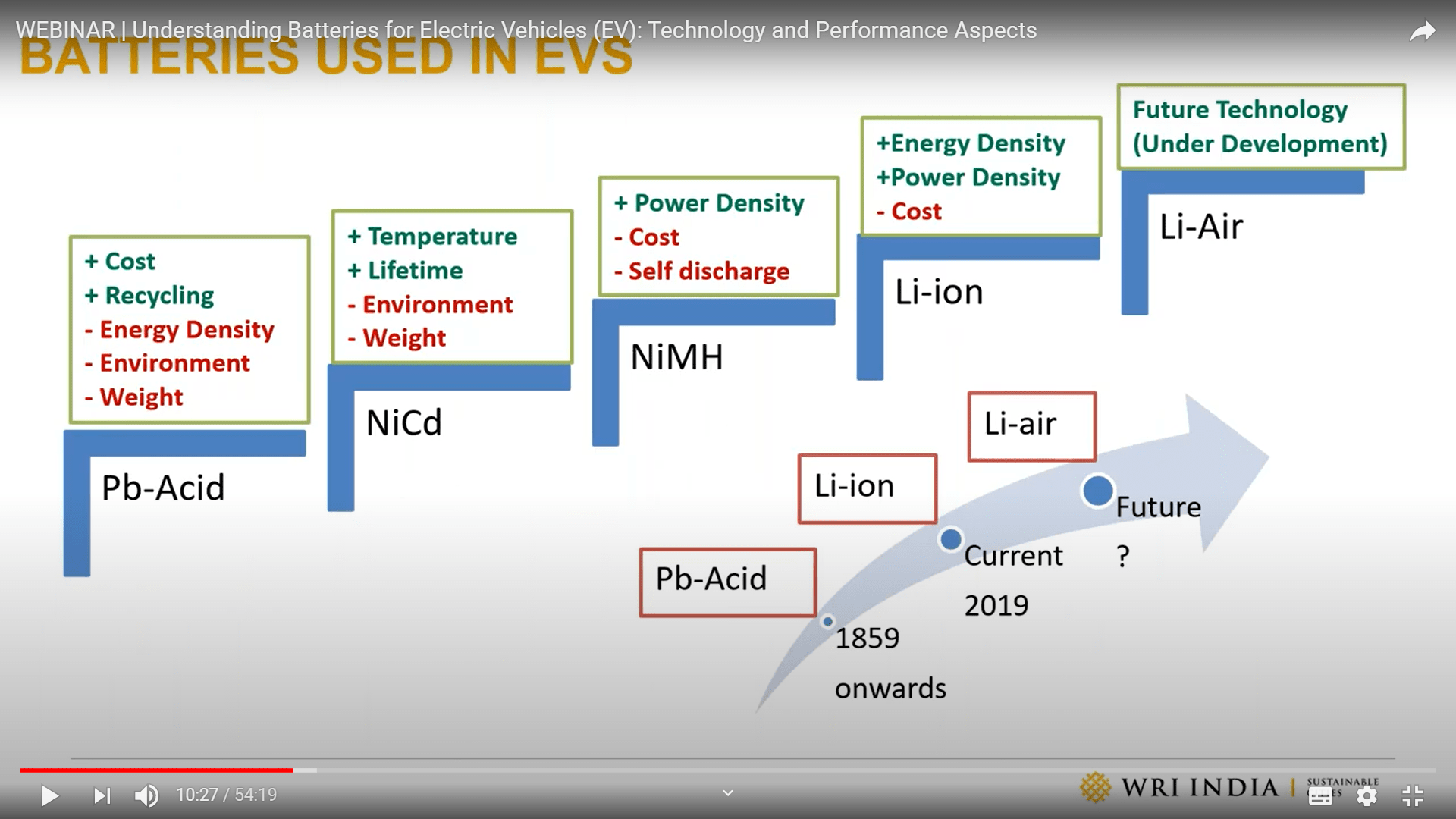

Battery Technology :

What battery are used in EV?

Four main types of batteries are

Lithium Ion, Nickel Metal hydride lead acid and ultra capacitor

Li battery are used since 1991 in all cell Phone, laptop, and MP3 players but the demand increases tremendously due to EV.

These are low maintenance light weight and more efficient than other batteries. Li batteries tends to be more expensive to manufacture than nickel metal hydride or lead acid batteries., It last for 8 to 12 years depending upon the climate and maintenance schedule.

The Indian market has a huge potential for Lithium-ion batteries, India required 3,50,000 tonnes per year. Up to now India exporting lithium-ion batteries from China, the battery pack cost is around 50–60 lakhs which is too expensive. In order to control the electric vehicles battery costs, Indian government encouraging lithium ion battery manufacturers in India.

List of Lithium ion Battery Manufacturers in India

ISRO

Amar Raja Batteries Ltd

HBL Power Systems

EON Electric Ltd

EXIDE Industries etc

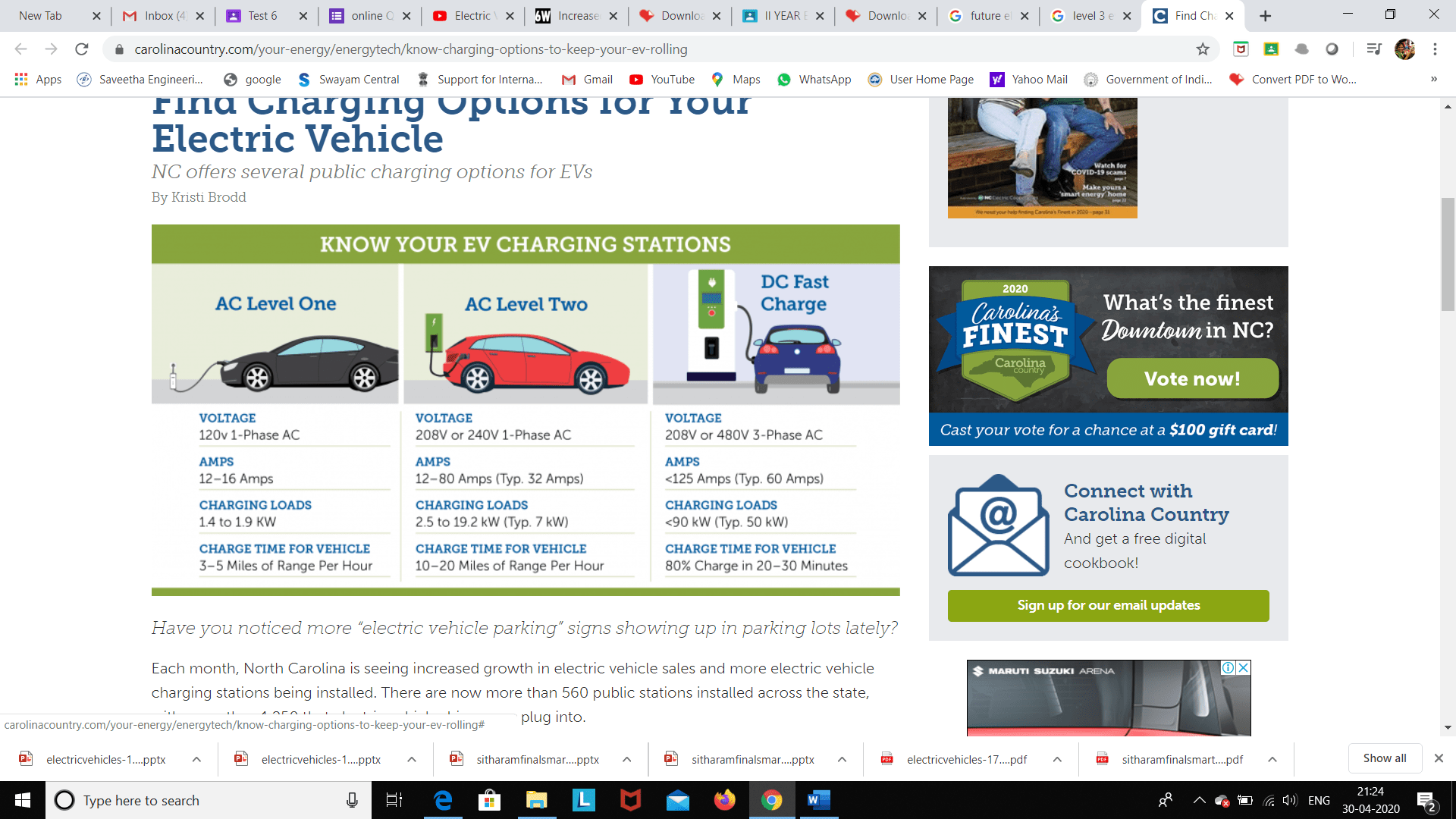

Charging can be done at home through a wall outlet or at a designated station in a public parking area. Charging occurs through the cars Electric Vehicle Service Equipment (EVSE)

What type of charging do we need?

Level 1 Home charging:

It uses a 120 volt plug and a standard outlet. No special equipment required and it can be done at home. It takes longest time to charge EV averaging about three to five miles per hour of charge.

Level 2 EVSE-Home charging :

EVSE use a 240 volt plug and typically need to be installed by an electrician. It can be used for either home or commercial charging.

Many electric car automakers provide purchase option for this charging at the time of vehicle purchase, and private companies also offers electric vehicle chargers.

It is much faster than level 1 charger, offering up to 60 miles of range per hour of charge. They are capable of fully charging an electric car battery in about 2 hrs.

Level 3 EVSE DC Fast charger:

This type of charging station is available in parking lots around town. They can deliver up to 100 miles of power in about 20 minutes of charging. It can be accessed through payment apps or specific cards setup for use at public charging stations.

Favourite full-electric models in March 2020 included the Audi e-tron (in both its new “50” and original “55” variants), the Tesla Model 3, the venerable VW e-Golf, the Nissan LEAF, and the Hyundai Kona EV:

Smart charging” is an umbrella term for a range of intelligent functionalities that help to manage charging stations in the most efficient way. These technologies will play an increasing role as growing numbers of stations and users need to be coordinated in the future, and it is well worth taking such requirements into consideration from the outset.

Benefits of smart charging include:

Grid management, Cost savings, Smart data.

Integration with broader networks: Smart charging allows stations to be recognized and integrated into broader networks, for example where companies wish to make their chargers available to the general public and easy to find on charging apps.

Market Overview:

The new proposal is to have only electric three-wheelers operating in the country by 2023, and only electric two-wheelers by 2025.

The government seems to have two dominant objectives – to control pollution and take the lead in an emerging industry.

India wants to become a “global hub of manufacturing of electric vehicles

But it will be a challenge to create a competitive advantage in electric vehicle manufacturing, or even a market for them.

Instead of charging batteries, which could be a time-consuming task, it intends to opt for a battery swapping model where a fully charged battery would quickly replace the discharged one at swapping stations. Bounce too is experimenting with battery swaps.

E-Mobility:

The e-mobility segment in India has undergone a major transformation owing to a number of fiscal and non-fiscal measures taken at the central, state and industry levels. These measures have enabled the smooth integration of electric vehicles (EVs) into the mainstream mobility segment.

At the central level, several ministries and departments, including the Ministry of Power (MoP), Ministry of Road Transport and Highways (MoRTH), Department of Heavy Industry, Department of Industrial Policy and Promotion, Ministry of Finance, Ministry of Housing and Urban Affairs, Ministry of New and Renewable Energy, Department of Science and Technology and NITI Aayog have taken initiatives to promote e-mobility.

NATIONAL ELECTRICAL MOBILITY MISSION PLAN (NEMMP) 2020

One of the most recent policy initiatives has been the release of the second phase of the Faster Adoption and Manufacturing of Electric Vehicles (FAME) scheme .Beyond providing support for a number of vehicles over a three-year period, it aims at catalysing the market, enabling the development of a supportive ecosystem for EVs, and crossing thresholds of economic viability that can initiate mass adoption of e-mobility solutions. The scheme is bolstered by global trends and a suite of additional policies at the central, state and city levels.”save 5.4 million tonnes of oil equivalent (mtoe) over their lifetime, resulting in cost savings of Rs 172 billion. This would result in a net reduction of 170 petajoules of energy and 7.4 million tonnes (mt) of CO2 emissions over the deployed vehicles’ lifetime.

Electric buses covered under FAME II will account for 3.8 billion vehicle km travelled over their lifetime.

The analysis also found that EVs sold until 2030 can cumulatively save 474 m toe, worth Rs 15,210 billion, over their lifetime. This will result in net reduction of 14 exajoules of energy and 846 mt of CO2 emissions over the deployed vehicles’ lifetime. Further, electric buses deployed through 2030 will account for 334 billion vehicle km travelled over their lifetime.

EV sales penetration of 70 per cent for commercial cars, 30 per cent for private cars, 40 per cent for buses, and 80 per cent for two- and three- wheelers by 2030 could be attainable.

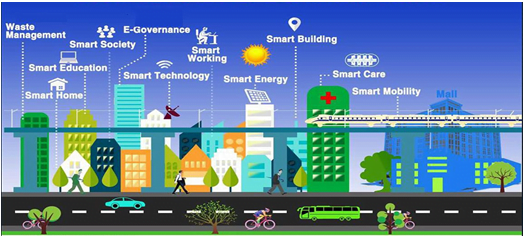

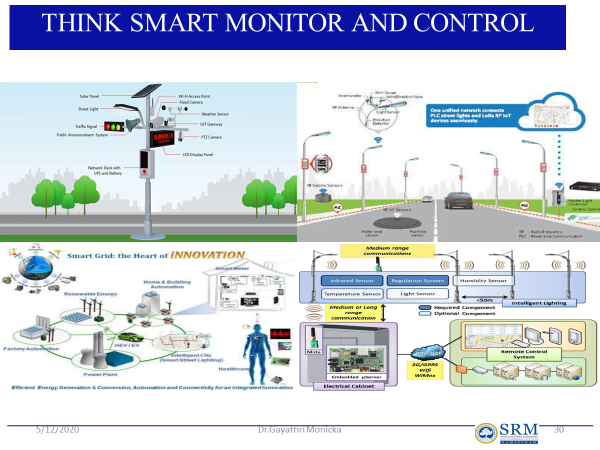

Smart City and Smart Live:

The Smart Cities Mission is an innovative and new initiative by the Government of India to drive economic growth and improve the quality of life of people by enabling local development and harnessing technology as a means to create smart outcomes for citizens.

The smart city initiatives were launched in 2015 in India, with the agenda to promote core infrastructure and sustainable life for citizens.

Government of India has released a list of 20 smart cities out of the 98 shortlisted for the ‘Smart Cities Mission’ as first step towards redeveloping urban area.

Do u know how many smart city are there in Tamilnadu?

12

The smart cities list include Tuticorin, Cuddalore, Salem, Tiruchi, Erode, Chennai, Coimbatore, Pondicherry, Tiruchirappoli, Tiruchi, Dindigul and Madurai which is planned among 98 top smart cities in India.

Is IOT is related to EEE?

Basically, IOT can work for enabling some sort of communication between the devices and also to control their functioning via internet. So, it can be readily used for automation and control of electrical and electronics equipment’s.

The applications of IOT are not limited to particular fields, but span a wide range of applications such as energy systems, homes, industries, cities, logistics, health, agriculture and so on.

IOT devices are used to monitor and control electronic, electrical and mechanical systems in homes and buildings in order to improve convenience and safety. The tasks of IOT in this domain include

- Smart lighting by adapting ambient conditions-based switching

- Web application and mobile apps enabled wireless and internet connected lights

- Smart appliances management and control

- Intrusion detection systems, alarm systems and surveillance systems

- Safety systems such as smoke and gas detection

- Home entertainment management such as video, audio and projectors

The major area where IOT deals with energy management systems is the smart grid. IOT extends the benefits of smart grid beyond the automation, distribution and monitoring being done by the utilities.

SCADA is one of the major application areas of IOT. SCADA allows the centralized monitoring and control of remote located generation and transmission systems. It consists of sensors, actuators, controllers and communication devices at the remote field place, and central master unit with communication systems at the controlling side.

Smart grid makes better use of available energy supply by optimizing electricity generation and distribution depending upon the load demand.

Creating an impact on environment with internet of cars:

Apart from the increased computing and sensing capabilities that allow smart cars to process input data from multiple sources, they present growing connectivity capabilities as well. Modern vehicles are connected over the Internet and cooperate with other vehicles or road-side units. A variety of technologies and different communication protocols are employed to serve different application contexts, such as vehicle safety, comfort, and entertainment. Specifically, connected vehicles are linked to the cloud, to other vehicles or even to road-side infrastructure utilizing wireless technologies (WiFi, 4G, LTE, etc.) Thus, smart cars are becoming the most sophisticated entity in the Internet of Things (IoT) era, hence they prevail as a replacement to modern cars introducing the era of Internet of Vehicles. Increased vehicle connectivity brings major challenges to the automotive research engineering groups that try to utilize all the available information sources efficiently. Existing approaches focus on processing data from single information sources, while their outcome is strongly affected by the information quality.

In other words, improve the coverage of the observation area and provide a better knowledge and perception of the environment of the vehicle, in order to make the driving experience safer, more comfortable and more efficient. In order to facilitate development of more sophisticated applications for road safety, infotainment, smart and green transportation, it is necessary to combine multiple heterogeneous sources of information. This new automotive era is realized with increasing communication capabilities of future cars (wireless connectivity) and transforms the current static perception of vehicles to an intelligent entity that dynamically interacts with its rapidly changing environment. Thus, future intelligent transportation systems will combine different sources of information and create an enhanced environmental awareness of the vehicle, offering an advanced resourceful travel experience for the passengers/motorists.

STUDENT’S FEEDBACK.

SALIENT FEATURES

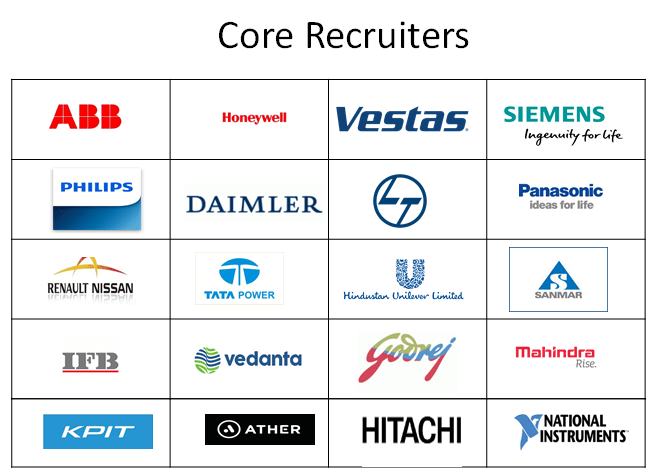

CORE STRENGTH OF THE DEPARTMENT

- Semester Abroad Program in Various Foreign Universities

- Dedicated and experienced Faculty members experienced in various fields of electrical specialization.

- Well established State-of-the-art laboratories for electrical machines, solid state drives lab, Power Electronics lab, skill development workshop and simulation lab.

- Refereed publication in indexed and peer-reviewed International Journals including IEEE Transactions, Springer, John-Wiley, Elsevier etc.,

- Have the abilities to absorb technological new knowledge and understand domestic and international industrial situations, which include funded projects from TNSCST, DRDO.

ACHIEVEMENTS

- III Year Started As A Entrepreneur In “Centre For Total Station And Computing” Which Is A Company Founded By Srm Institute Of Science And Technology Students Under The Guidance And Support Of SRM IST.

- Consistent University Rank Holders from the department. / gold medal

- Akash Gokhareprabudha B.V, Vikas Kumar, Ramananda Sagar Project Smart Power Stabilizer Has Already Been Qualified To The Quarter finals Of The Iicdc Competition Wherein The Texas Instruments Has Provided The Vital Components To Make The Working Prototype.

- Students publish individually many technical papers in conferences and symposiums

- Faculty members were awarded in international forums including USA, Japan and (golden globe)

RESEARCH THRUST AREAS

- ANALYSIS AND CHARACTERIZATION OF SWITCHED RELUCTANCE MOTORS & FLUX REVERSAL MACHINES

- WIRELESS SENSOR NETWORK

- VOLTAGE STABILITY IMPROVEMENT IN MICRO GRID

- POWER QUALITY IMPROVEMENT USING FACTs DEVICE IN TRANSMISSION SYSTEM

BEST PRACTICES

- Semester Abroad Program in Various Foreign Universities

- Recognized Research Centre To Pursue Ph.D.,

- Faculty members are either Ph.D qualified or Pursuing Ph.D.,

- Value Added Courses and Soft Skill Training targeting for better employability

- IEEE, IE(I) students Chapter and various Professional Clubs for academic growth

- Industry institute interaction through Internships, Project Works, Comprehension, Workshops, Visits and Guest Lectures.

- ICT enabled experiential learning through design / fabrication / project

- Choice Based Credit System to widen the student’s knowledge

- Organizing national conferences, Seminars, Workshops, Symposium, Faculty Development Programmes, Student Technical Competitions etc.

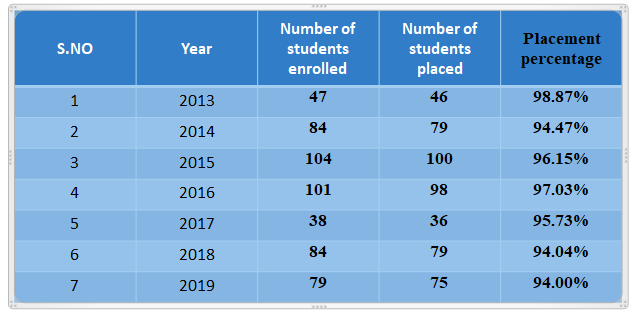

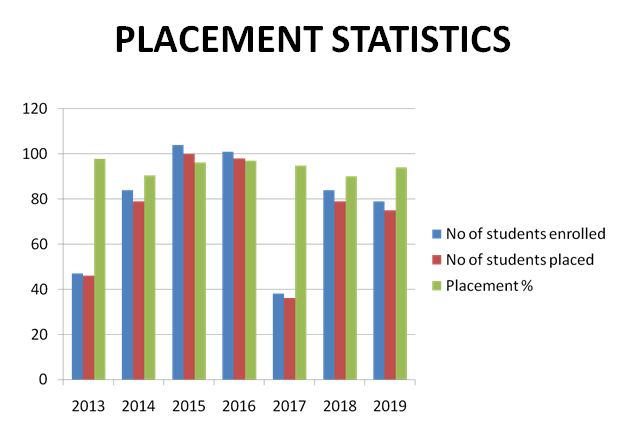

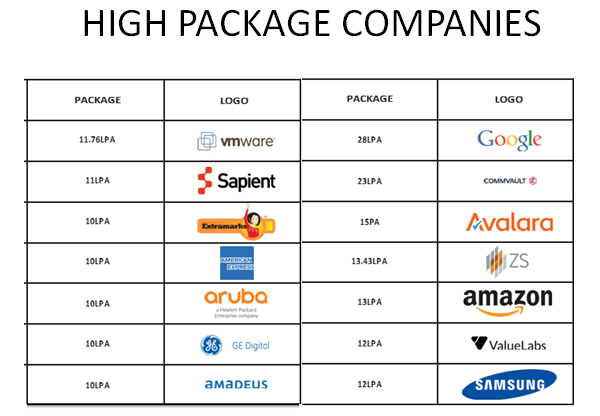

PLACEMENT STATISTICS

HIGHER STUDIES